With our long-term supplier experience in the automotive industry since 1996, our unique and cost-effective scratch tester, Dyna-SPA®, has been selected to be the tester in BMW GS 97034-11 specification for variable shoes sole test. Additionally, Dyna-SPA® can fulfill BMW GS 97034-8, -9 as well.

Damage to a surface due to abrasion, scratch, mar, scrape and punch is one of the main reasons for the disturbance of a product's quality. In many real applications, deep scratch or severe abrasion occurs during a fast and high dynamic motion, e.g. a deep long scratch by a key on the exterior paint of a car. This high dynamic scratch occurs at a high speed up to 150 cm/s. Dyna-SPA® , is the only machine which can simulate the high dynamic scratch, punch and abrasion tests within one machine with freely programmable speed (up to 150 cm/s) and stroke (up to 120mm). It complies with over 50 international standards (ASTM/DIN/ISO) for the following applications:

• Universal Scratch Test

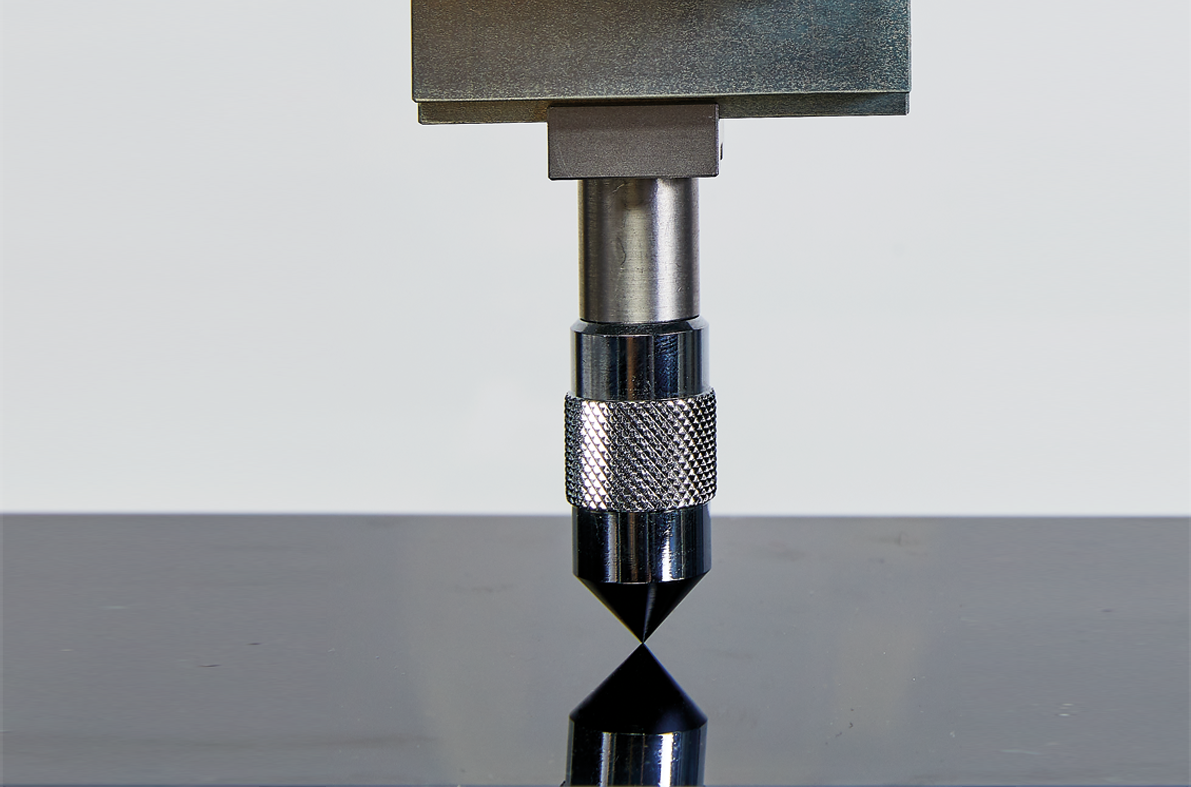

• Nail Scratch Test

• Pencil Test

• Key Scratch Test

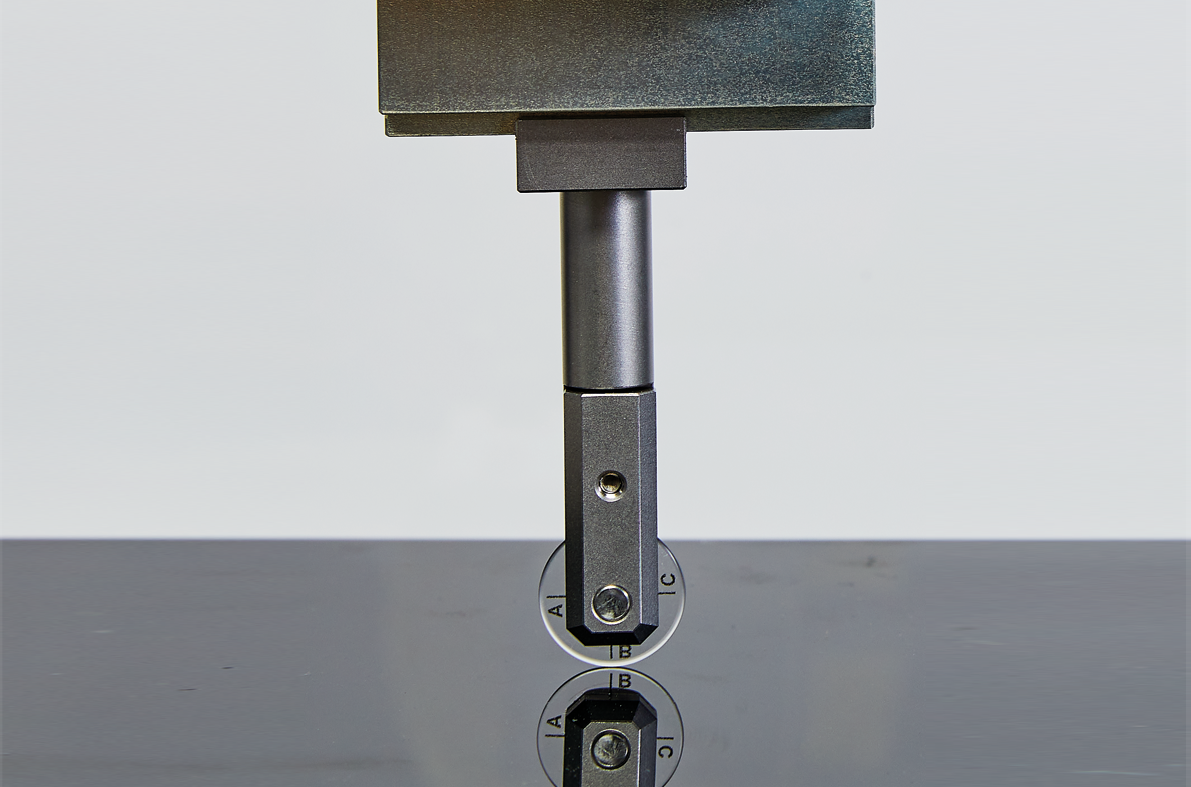

• Cross-cut Test

• Universal Abrasion Test

• Shoe Sole Test

• Crockmeter Test

• Wire/Cable Abrasion Test

• Film/Packaging Material Abrasion Test

• Magnetic Stripe Abrasion Test

• Cleaning/Scouring Pad Abrasion Test

• Tooth Abrasion Test

• Scuffing Abrasion Test

Dyna-SPA® tester is designed to test either flat surfaces or curved products, making it versatile to evaluate finished products of all sizes and all materials. A variety of optional test tips, test textiles, test media and sample clamps is provided to perform different types of abrasion, scratch, mar and punch tests. And it is also suitable for both wet and dry tests.

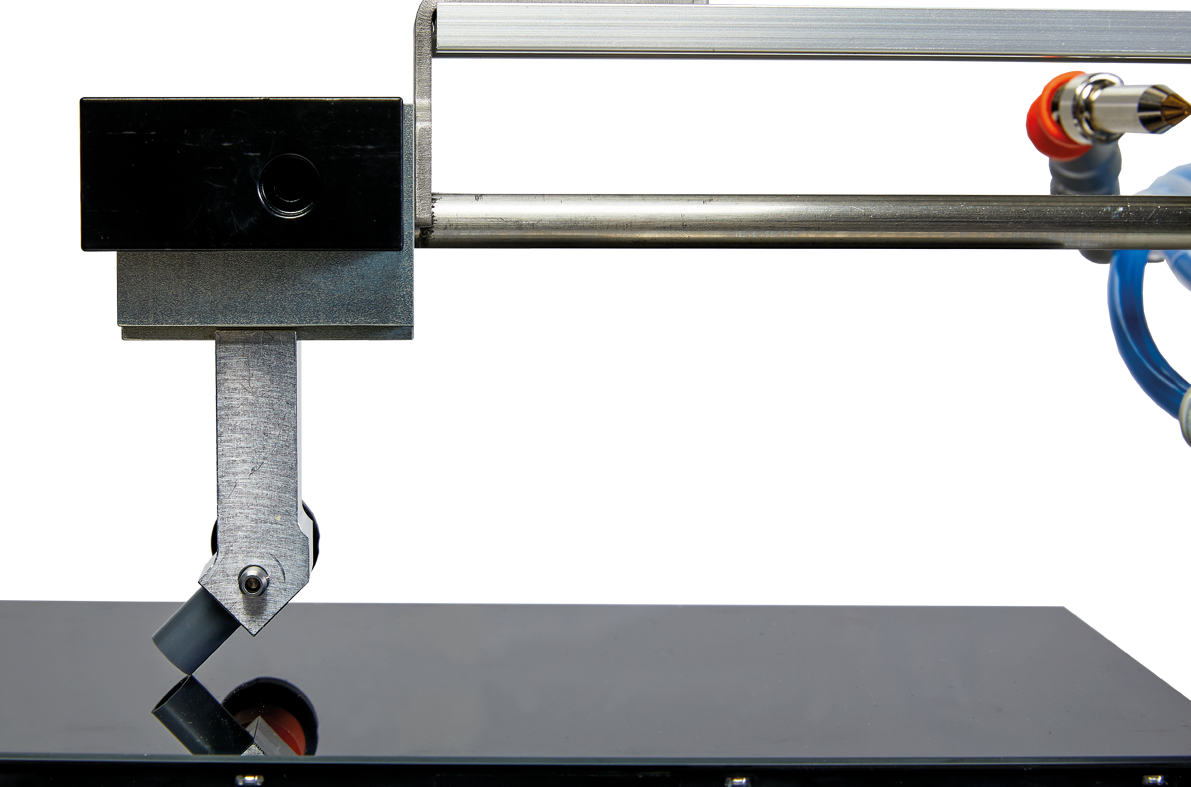

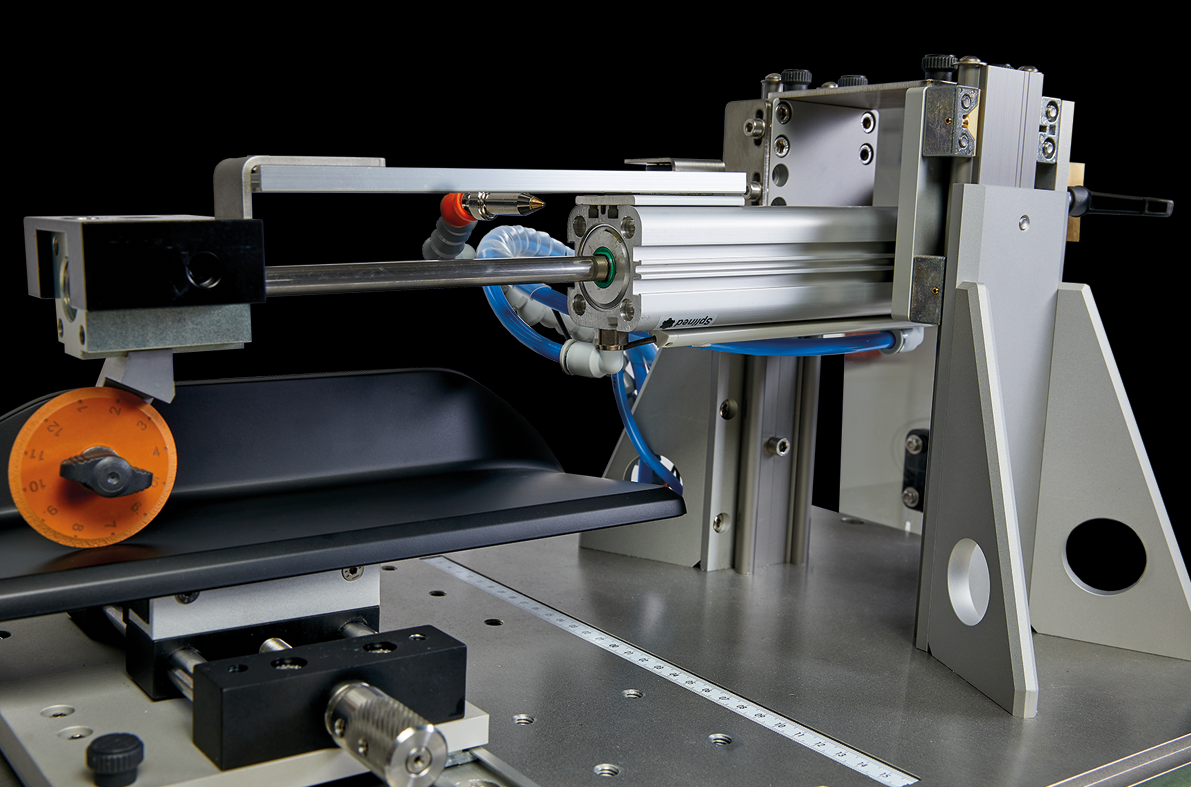

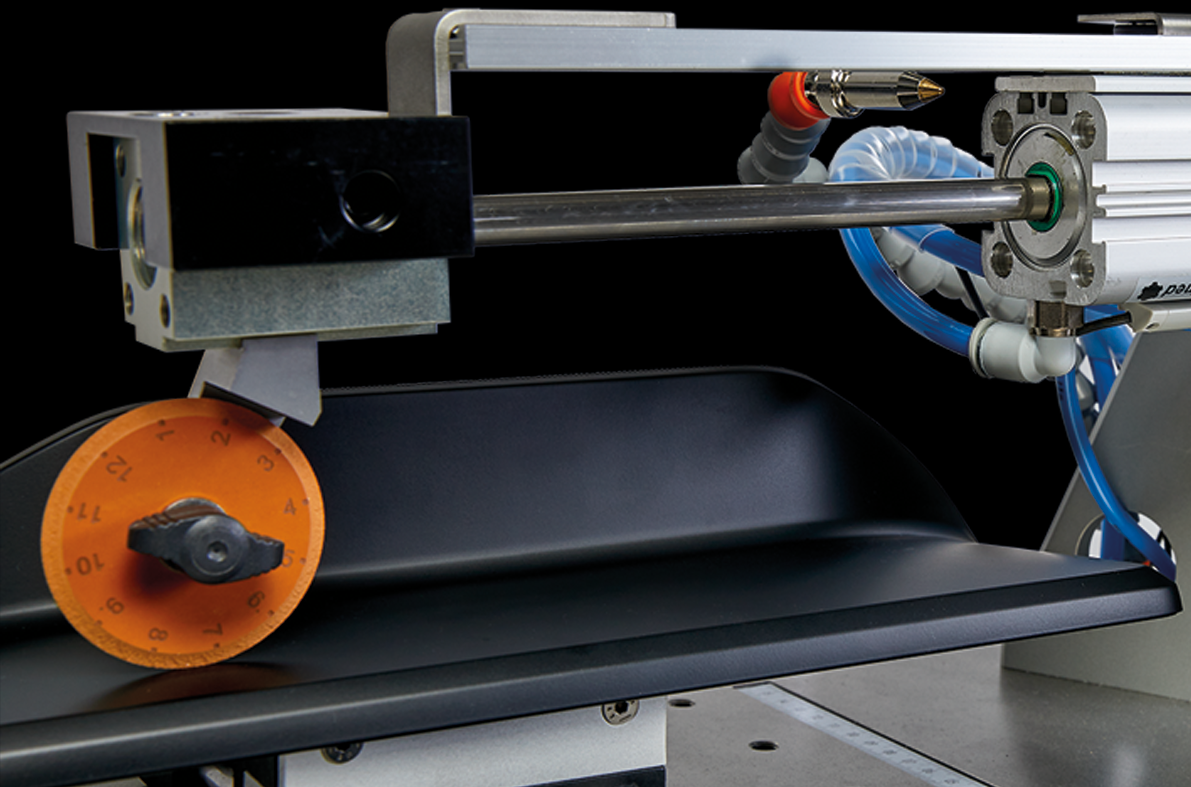

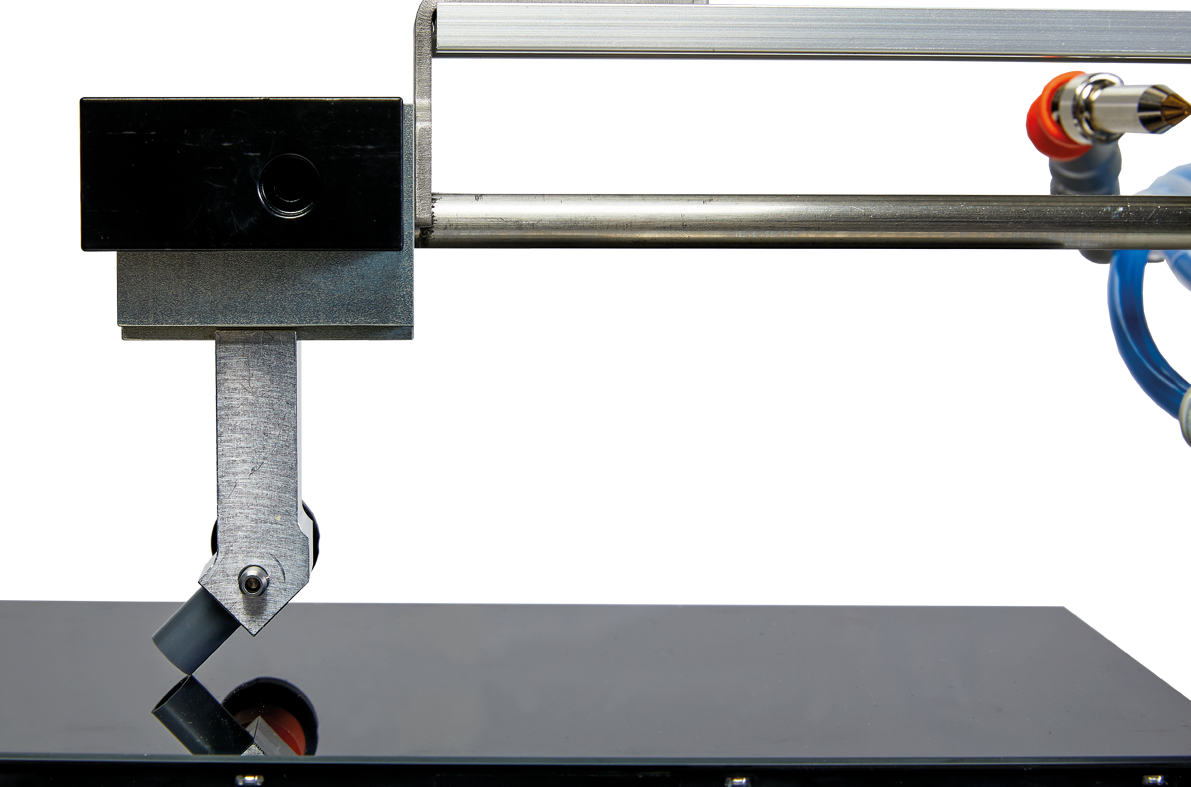

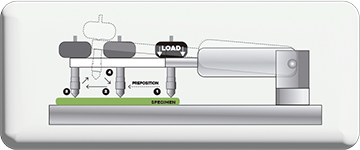

Dyna-SPA® tester is built with a horizontal piston rod driven by a pneumatic cylinder that moves in a linear motion, either one-direction or reciprocating. At the end of the cylinder is a movable assembly which allows the cylinder and the arm to move freely in the Z-direction. Therefore, the tip follows the shape and surface structure. The tip is mounted to the end of the piston rod and a dead weight is mounted on the top to generate a load in Z-direction onto the test sample. As the horizontal rod moves, the test tip raises or lowers vertically to follow the curvature of the test sample. In addition, the pillow block can be moved up and down, therefore the samples with a wide range of thicknesses can be tested.

• Pneumatic system drives the tip wheel to the prepositioning point “2” to ensure the right velocity for the test;

• Then the tip is moving from point “2” with a certain stroke to point “3” at pre-defined speed;

• A pushup rod will lift the pneumatic cylinder to position “4” and reside back at the position “2” for the next cyclic linear motion;

• An opposite cycle from position “2” to “4”

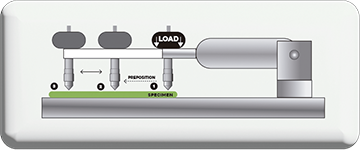

• Pneumatic system drives the tip wheel to the prepositioning

• point “2” to ensure the right velocity for the test;

• Then the tip is moving back and forth be- tween point “2” and “3”

• at pre-defined speed, the inward and outward speeds can be different.

Dyna-SPA® tester is used to test the resistance property of material and surface

against scratch, abrasion and punch. The samples can be lab samples or finished

products either flat or with curvature.

Dyna-SPA® is widely used as a standard for many industries:

• automotive components

• painted/coated parts

• printed graphics/images

• optical products

• leather

• textile

• medical products

• packaging materials

• flexible films

• wires and cables

• magnetic stripes

• electronics

• rubber

• home appliance

• floor

• ceramics

• furniture

• coating and color

Dyna-SPA® tester has an adjustable program which enables the user to select the test mode, test speed, stroke length, test load and others. According to the test method, the test condition can be set up freely in the software.

Dyna-SPA® tester can perform various tests which comply with many ISO, ASTM, BS, GB/T standards. Please contact us for information on the test standards that can be performed by Dyna-SPA® to evaluate the resistance of a material surface to scratch, abrasion, mar, scrape and punch.

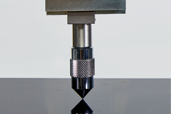

There is a variety of adapters within the Dyna-SPA®, for example, key scratch, cross cut scratch, crockmeter abrasion, and many more.

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany