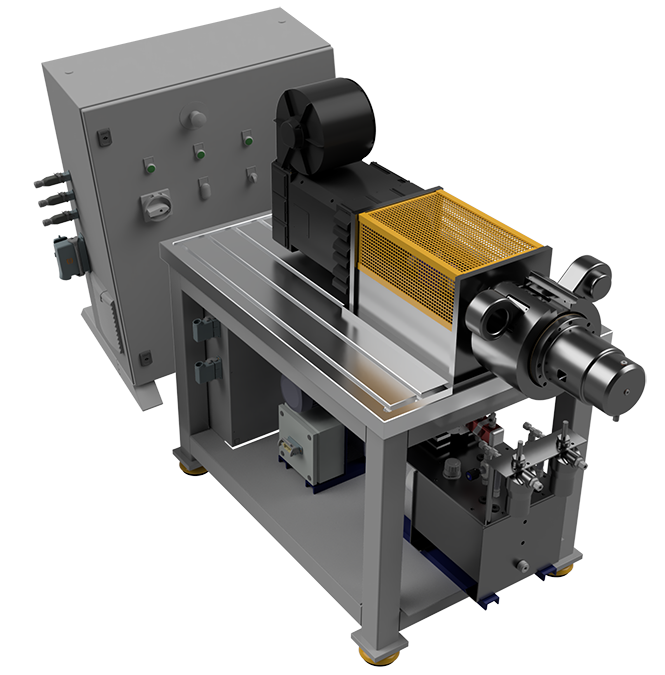

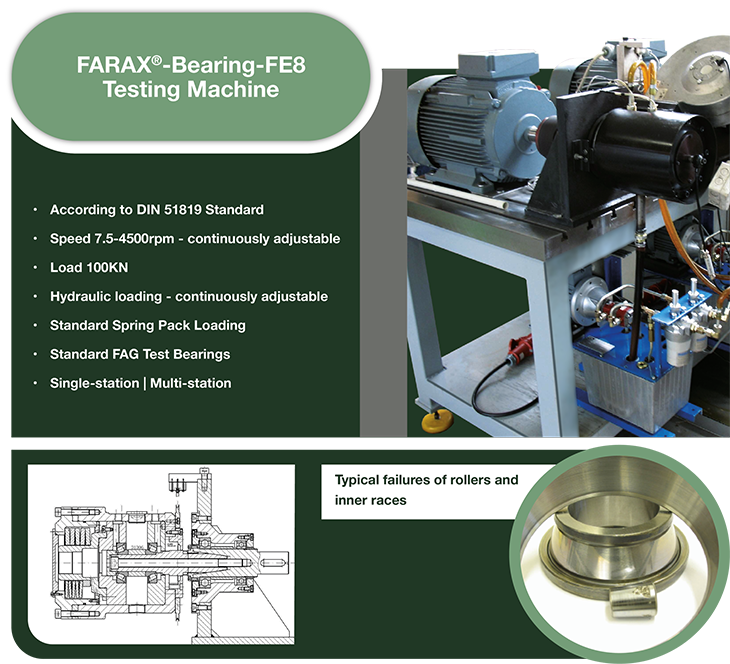

Standard FE8 test rigs with easy adjustable hydraulic loading

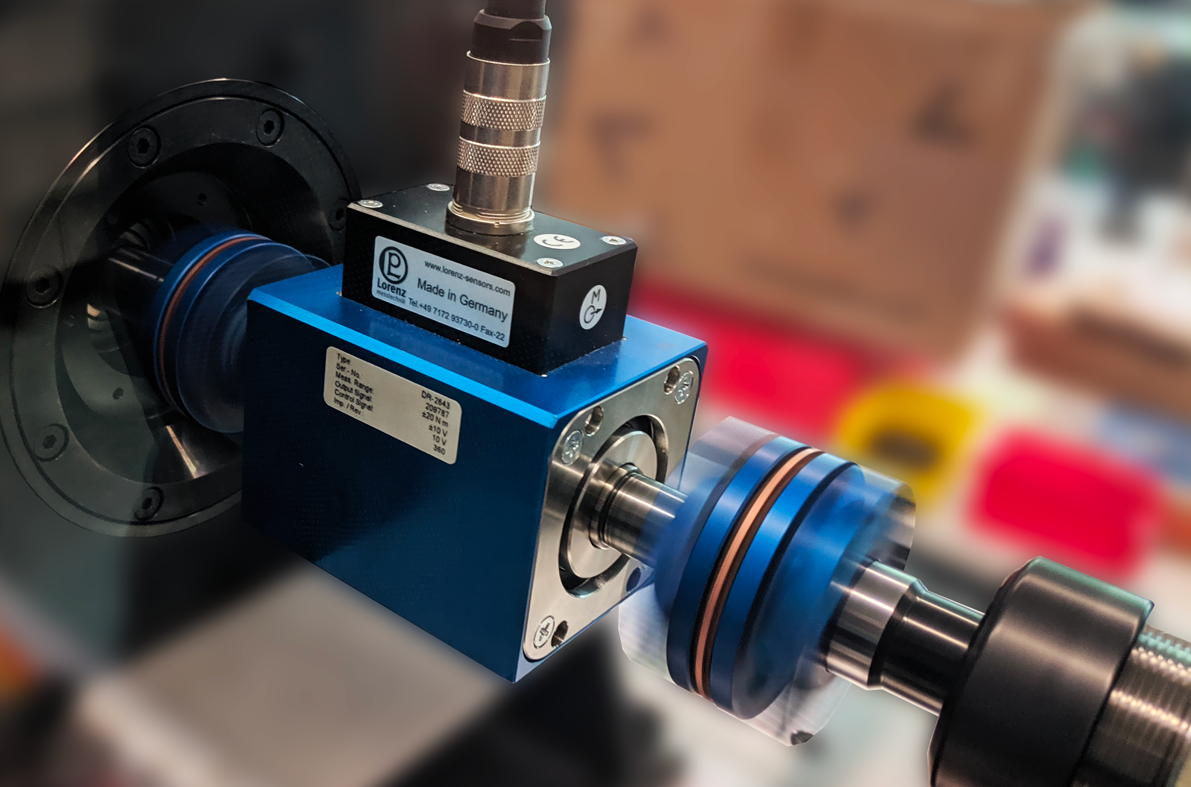

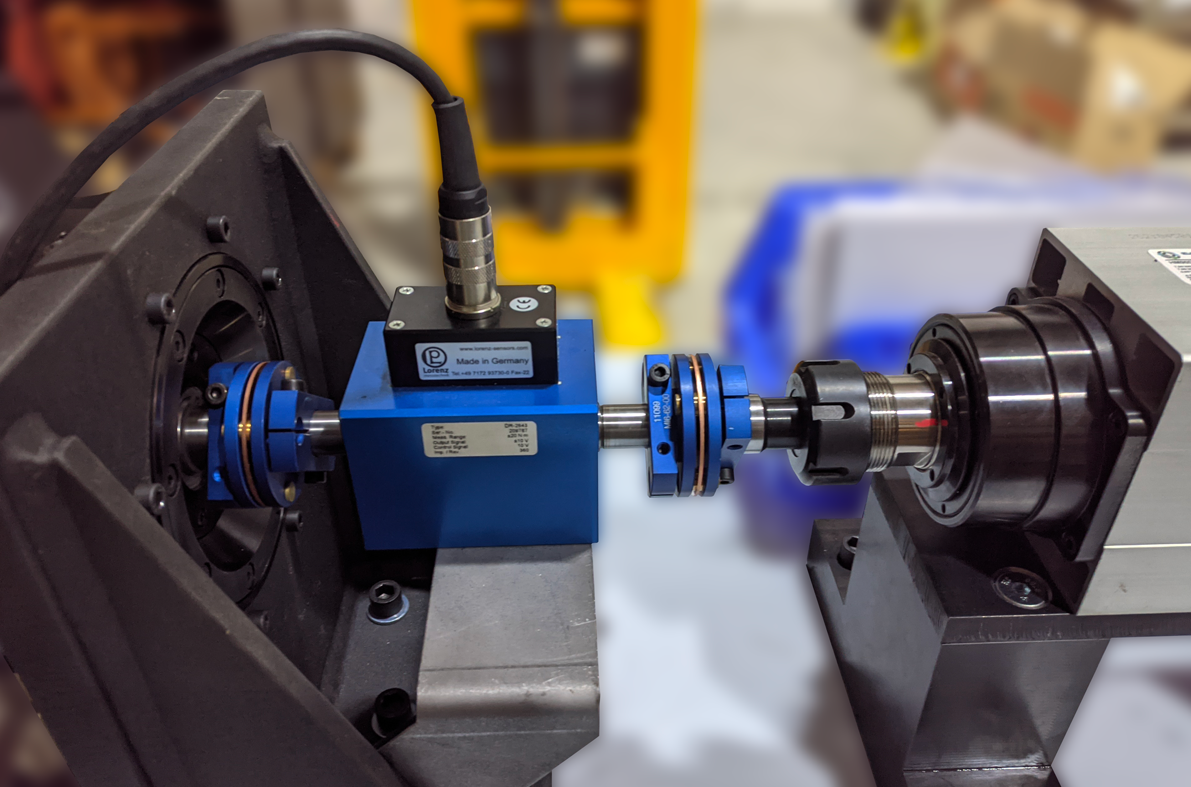

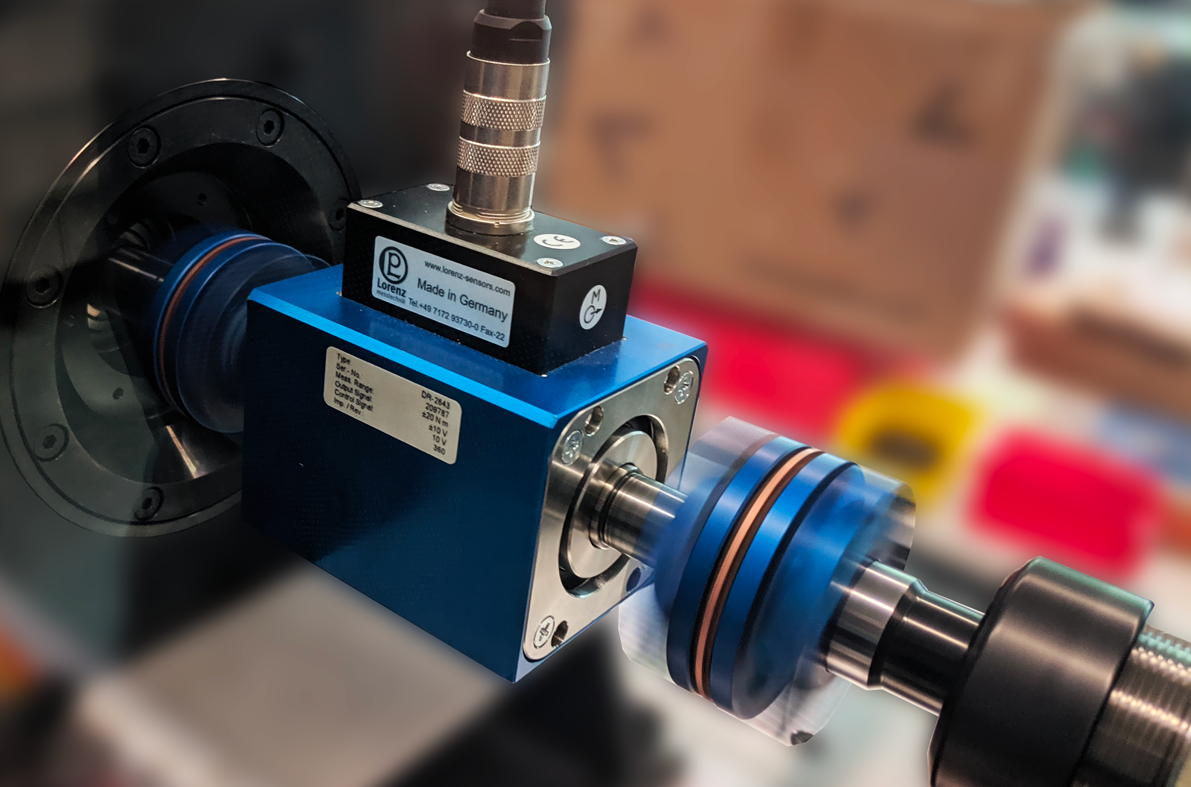

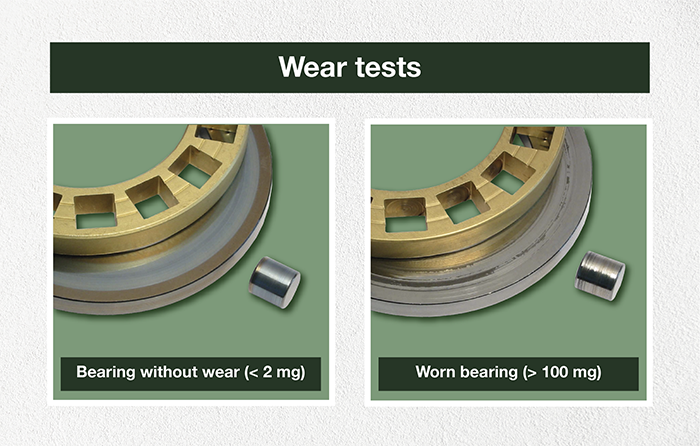

The standard FE8 test rig is used to examine lubricating oils and greases with regard to their wear and friction behavior under lubricant and bearing-specific influences according to DIN51819 standard and VW, ZF, Mercedes methods. Innowep supplies an advanced FE8 test rig with hydraulic loading which is suitable for variable loads and speed controls during test. The FARAX-Bearing-FE8-H equips with an additional hydraulic load system. Online measurements of the test rig include bearing temperatures, load, speed, torque, etc.

Standard FE8 test rigs with classic springpack loading

FARAX-Bearing-FE8-M test rig fulfils the DIN51819 standard and other test methods, including FAG 2-step, VW test and ZF pitting test methods. This classical standard FE8 test rig is equipped with a set of springpack, a high press with load cell, to evaluate the wear and friction behavior under oil and grease lubrication

The FARAX-Bearing FE8 test rig is suitable for testing lubricants under very high loads. Typical test procedure includes the following:

1. Tapered roller bearing 31312 A, 75 rpm, 80 kN, 80°C, 500 h;

2. Tapered roller bearing 31312 A, 75 min-1 / 80kN, 80°C , 500 h, wear of rolling bearing.angular contact ball bearings 7312 TP / Fa = 80 kN, P/C = 0.54, n = 7.5 rpm

3. 500h at 200°C, 7.5 rpm, and an axial load of 80 kN.

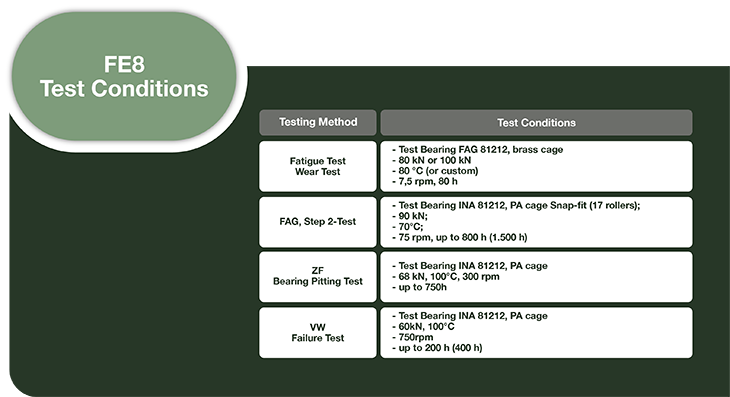

Other test methods have been developed in the past decades for various testing applications, examples are shown below.

We provide two version of FE8 test rig, one is the upgraded advanced version: Standard FE8 with hydraulic loading

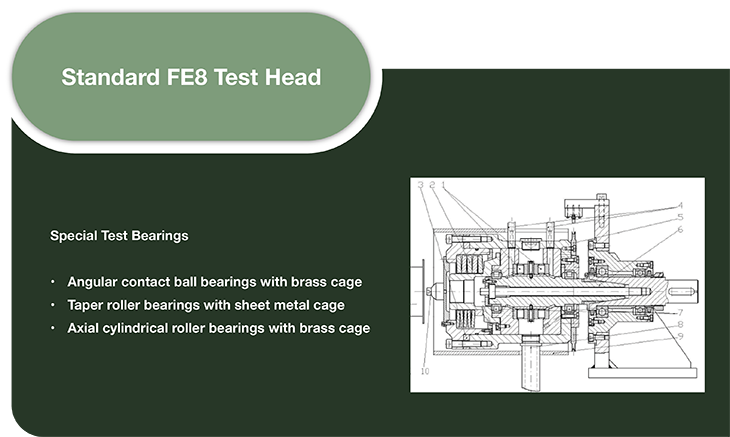

A standard test head is connected to the drive unit which has a rotational speed up to 4,500 rpm. The bearing load is applied in the axial direction with a hydraulic unit up to 100 KN. An insulating cover attached around the test head, is to minimize the heat radiation during heating operation and prevents the risk of burns. To ensure easy and precise assembly and disassembly of the test head and test bearing, assembly and disassembly tools are included in the scope of delivery.

Another version of the FE8 test rig is Standard FE8 with springpack loading, in which a set of conventional springpack and a high press up to 100 KN are supplied for load application.

With our rolling bearing lubricant test rig FARAX-Bearing-FE8, industrial products including lubricants, rolling bearing materials and rolling bearings can be examined under certain specific operating conditions according to DIN 51819 standard and many more test methods. Our FARAX-Bearing-FE8 test rig can also be adapted to a wide variety of operating and environmental conditions.

Generally speaking, when a rolling bearing is under fatigue test with several unfavorable conditions, such as high or low speed, load, temperature, or if another parameter is particularly critical, the following questions have to be considered: Which option is the most suitable for achieving satisfactory running behavior and long-term problem-free use?

Should a particularly suitable lubricant, or a specific amount of lubricant, or an adapted rolling bearing material or a specific rolling bearing design be selected? Our FARAX-Bearing series test rigs allow the test conditions to be adapted to the respective application in a wide range of areas, such as speed, load, temperature, bearing type, bearing size and lubrication.

“Made in Germany” Engineering

It is at the heart of our family business.

We develop and produce quality testing machines for evaluation

of your materials, surfaces and coatings.

Fax: +49 (0)931 32298 – 12

E-Mail: info@innowep.com

New Address:

Friedrich-Bergius-Ring 11 | 97076 Würzburg | Germany